Inventory Management Automated. Simplified. Perfected.

RFID Inventory management custom designed to fit within the processes you already use.

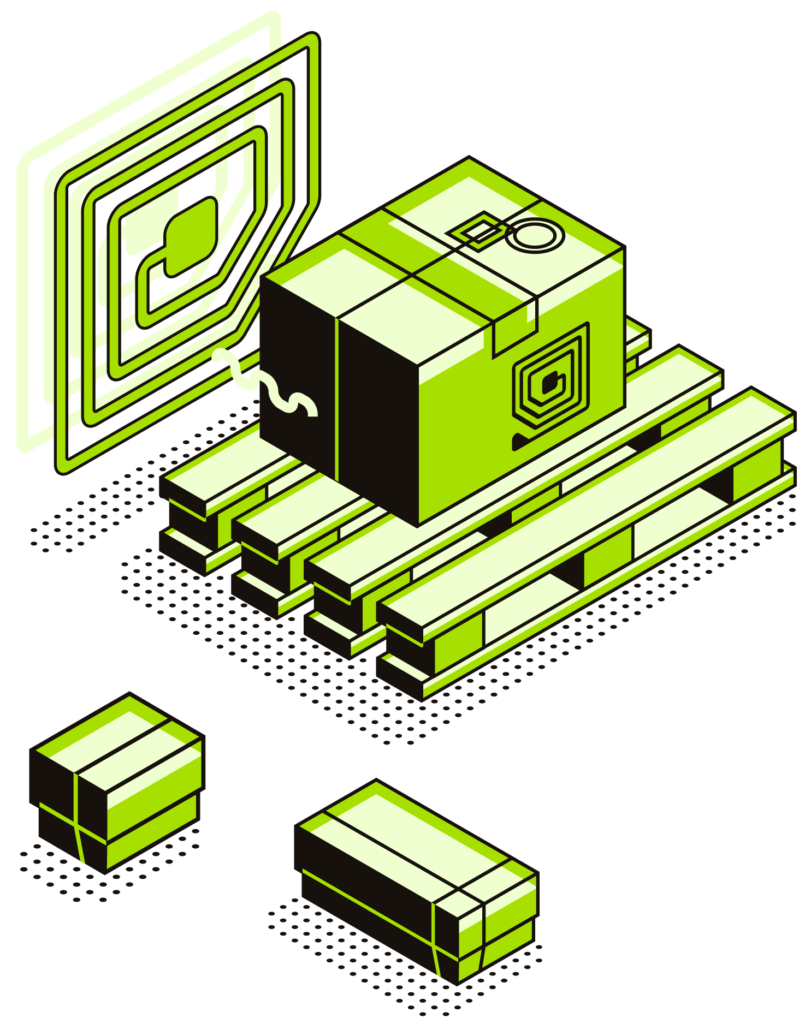

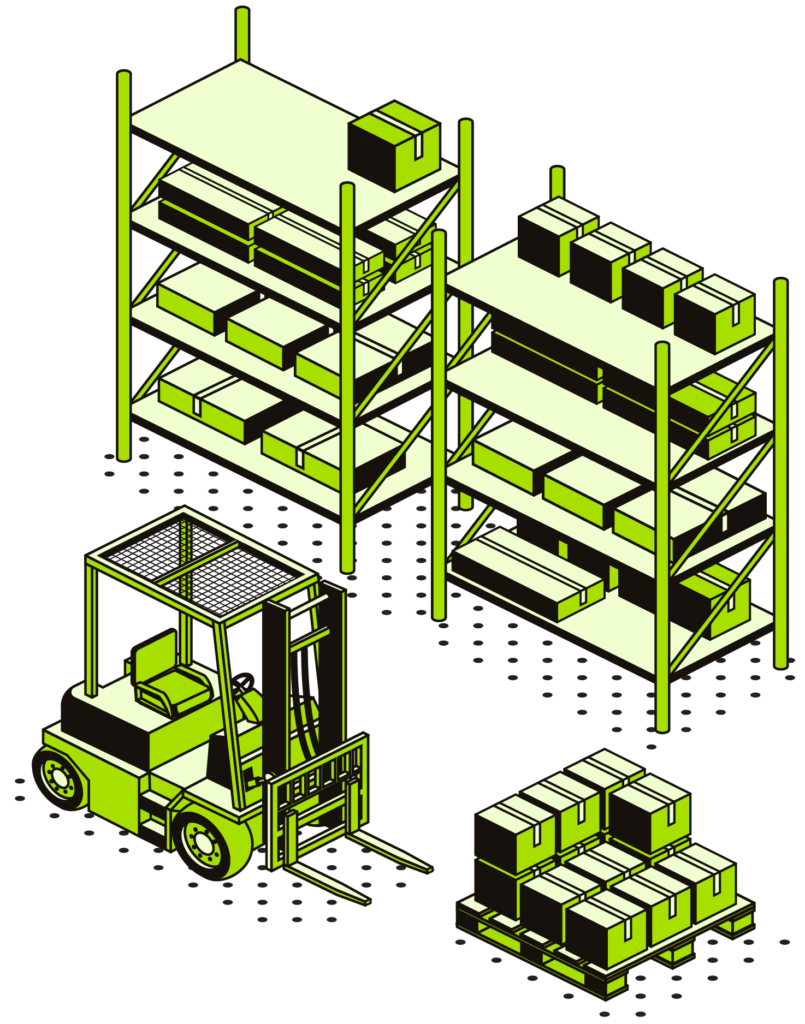

When a part is picked at GLR’s warehouse and the pick ticket identifies it as a Scanopy part, the operator will create a label with an embedded RFID chip. All RFID information included on that chip will be transmitted to the Scanopy cloud and identified as “in transit” to your location.

[RFID tags include important information, such as: order number, part number, quantity, batch number, cure date, country of origin, customer information, and more! ]

Just do what you always do! Our locally installed Scanopy antennas will recognize our RFID tags when you store our parts on your stock shelves. Scanopy items will now register as “in-stock” on the Scanopy dashboard.

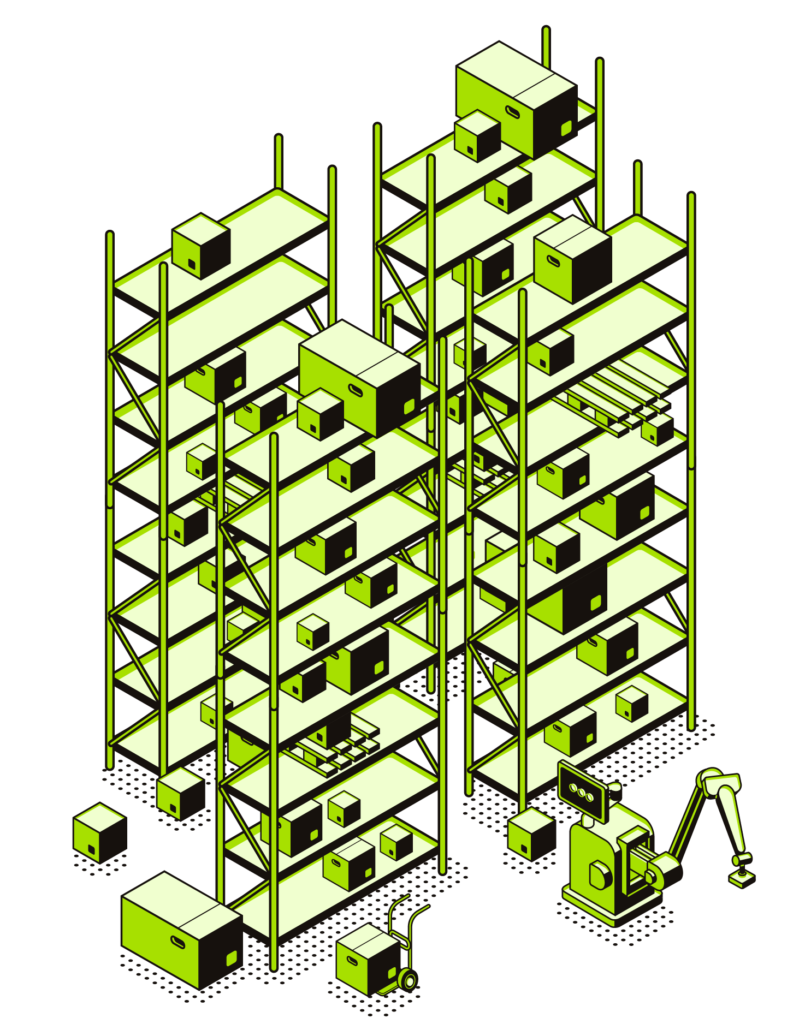

Our always-on antennas scan the room more than 60 times every second! The canopies are programmed to recognize GLR-specific coding, so they wont get tripped up by other tags in the area.

Use or Sell your inventory as needed. Once the box or bag is taken from the canopy area, Scanopy will register the parts as consumed. This will send an updated inventory count to your Scanopy dashboard.

No worries! Simply return the parts to the canopy area and Scanopy will consider the parts back in stock. Easy Peasy!

When the on-hand and in-transit inventory falls below the agreed target quantity for a specific part number, GLR will auto-replenish or signal your buyer to order more.

Our proprietary Scanopy dashboard shows the last 12 weeks of demand history and our trained account specialists can recommend raising or lowering your reorder point based on recent demand changes.

Great Lakes Rubber is among the companies employing battery-free RTLS solutions from Accu-traq. Together with RF Controls’ overhead CS-445B Smart Antennas (Winner Best New Product RFIDJL’19) the solution delivers pinpoint location data using standard RAIN RFID tagged inventory, assets and forklifts as they move inside the four walls in real-time. GLR is a well-established rubber products and fittings distributor located in Wisconsin and Illinois. Warehouses serve customers globally, stocking inventory for over 30,000 items from over 200 manufacturers. Automated ordering and enhanced efficiency is a critical component to process visibility and growth.

Author: Claire Swedberg

Date: June 12 2022

SCANopy RFID inventory by Great Lakes Rubber is a simple, virtual, vendor managed inventory solution that monitors GLR’s product at your facility; without the need for you to alter your process or to connect the system to your IT infrastructure. Great Lakes monitors your on-hand stock in real-time and issues replacement orders based on pre-approved blankets and desired stocking levels. Call GLR to set up a visit to your warehouse, or for a custom SCANopy installation.

Introducing SCANopy into your factory or warehouse can save your company time and money; freeing up valuable labor hours and simplifying your inventory process.

Our unique, and largely hands-off approach automates the stocking and consumption process, allowing you to spend more time selling and building, and less time buying.